Our latest round of experiments have convinced us that we will not be able to achieve the level of purity in the plasma we need for high density as long as we have joints between metal pieces in the cathode. Even with our very careful use of indium, sufficient contact resistance remains to cause significant vaporization of copper. So, despite the additional expense involved, we have decided to upgrade the cathode to a single monolithic piece of tungsten. This single piece will incorporate the cathode plate, the cathode rods and the underlying plate that attaches to the transmission plates that carry the current back to the capacitors. Thus the plate will only have a current connection outside the vacuum chamber. Both our experimental experience and materials theory indicates that vaporization from the tungsten itself should be minimized, and should fall well below the requirements we need. As far as we know, such monolithic construction is new for plasma focus device design.

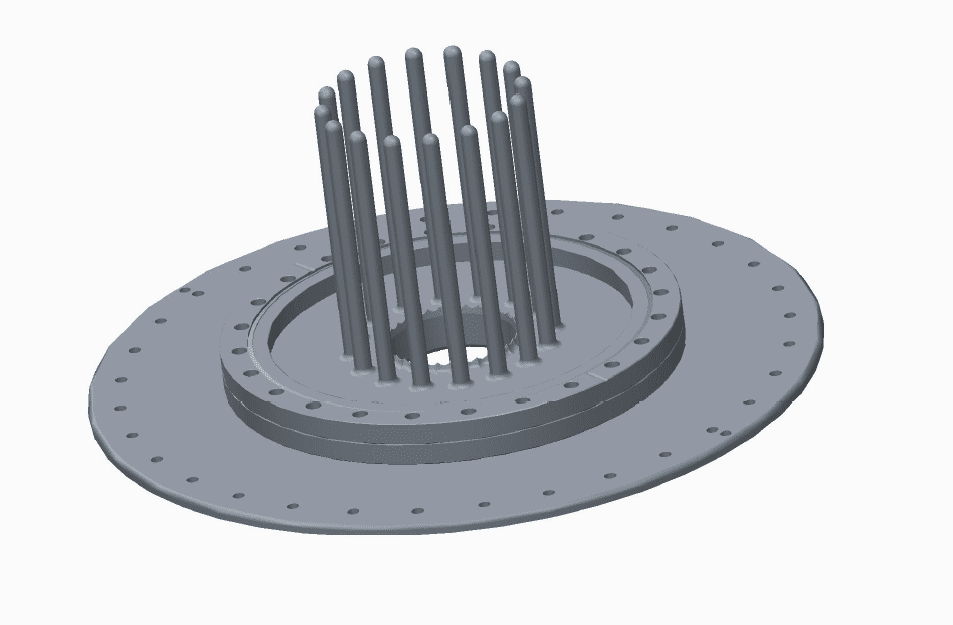

However, a key consideration in the new cathode design is the brittleness of tungsten. Complex tungsten pieces like ours are formed by sintering—pressing together tungsten powder. This process does not give the tungsten its full strength and makes it vulnerable to sudden impacts. When the current flows through the electrode, the magnetic field will force the cathode outwards while it pinches the anode inwards. So we have to design the new cathode to withstand repetitive sudden stresses of this sort. On possible design involves replacing the rods with vanes that will be much more resistant to stresses, as shown here. One of our student research associates this summer, Arya Ghaseminejad, is helping to prepare various design alternatives. These will be tested with CAD simulations with the help of LPP Board of Advisor member Rudy Fritsch. In this way we can ensure in advance that a new and more expensive monolithic cathode will also be long-lasting.

In order to measure in real time the amount of metal impurities in the plasma, we have purchased a digital UV spectrometer. From the ratios of the strengths of the bright lines produces by deuterium and by the metals we should be able to calculate the impurity levels for each shot. Our other student research associate, Kyle Lindhiemer, will be calibrating this spectrometer and we will probably be doing some shots with the old cathode to get a baseline comparison for our monolithic model.

This news item was part of LPP’s July 15th, 2013 Focus Fusion report. See full report.